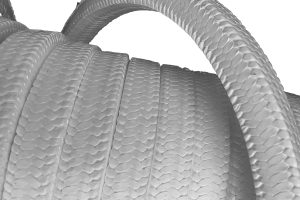

ePTFE Yarn

For Compression Packing Braiding

The expansion process for PTFE creates a micro-structure of interconnected PTFE nodules and fibrils, creating an extremely strong micro-structure that is considerably higher in tensile strength. This strength results in far more resistance to cold flow, which then decreases creep relaxation when compared to traditional non-expanded fiber. The resulting fiber is still 100% PTFE and, therefore, maintains all the inert properties of PTFE with a pH range of 0-14 with few exceptions. It has low surface free energy (18.5 dynes/cm2 or .00027 psi) with excellent self-lubricating values and can withstand continuous service in temperatures from -200º C to 260º C (-328º F to 500º F).

Specification:

- Specification: 1.5g/m 2g/m 2.5g/m 3g/m 3.5g/m 5g/m

For Compression Packing Braiding

ePTFE / Graphite creates a compression packing fiber that combines the properties of each material. The graphite content creates a fiber that is thermally stable and has a high thermal conductivity. The ePTFE fiber provides strength and high conformability and enhances the ability of the packing to be easily installed and removed. The combination of the two materials creates a packing with a low coefficient of friction, good dimensional stability, and high resistance to chemicals with a pH range of 0-14. ePTFE / Graphite fibers are only limited by temperature and can give continuous service up to 288°C (550°F). These yarns are generally used in applications where surface speed is under 20 m/s (4000 FPM).

Specification:

- Specification: 1.5g/m 2g/m 2.5g/m 3g/m 3.5g/m 5g/m

Compression Packing

Shaft speed ------ 9 m/s (1800 fpm)

Stuffing box pressure ------ 22 bar/325 psi

Process fluid temperature ------up to 230ºC/450ºF

Process fluid pH level ------ 0-14

Pump speed ----- 18m/s (3600 fpm)

Stuffing box pressure ------ 22 bar/320 psi

Process fluid temperature ----- up to 260ºC/500ºF Process fluid pH level ------ 0-14

Shaft speed ------ 10 m/s (1969 fpm) Stuffing box pressure ------ 25 bar/360 PSI Process fluid temperature ------ -100℃to 250ºC/-148ºF to 482ºF Process fluid pH level ------ 2-12